MVI helps Chinese resin manufacturers occupational exposure limits

In line with China’s newly updated occupational exposure limits for Chemical Hazardous Agents in the Workplace GBZ 2.1-2109 regulations.

Purolite is a leading manufacturer of quality ion exchange, catalyst, adsorbent and speciality high-performance resins for complex regulatory environments including biotechnology, pharmaceutical, food, fine chemical and electric power generation. The company focuses 100% of its resources on the development and production of resin technology.

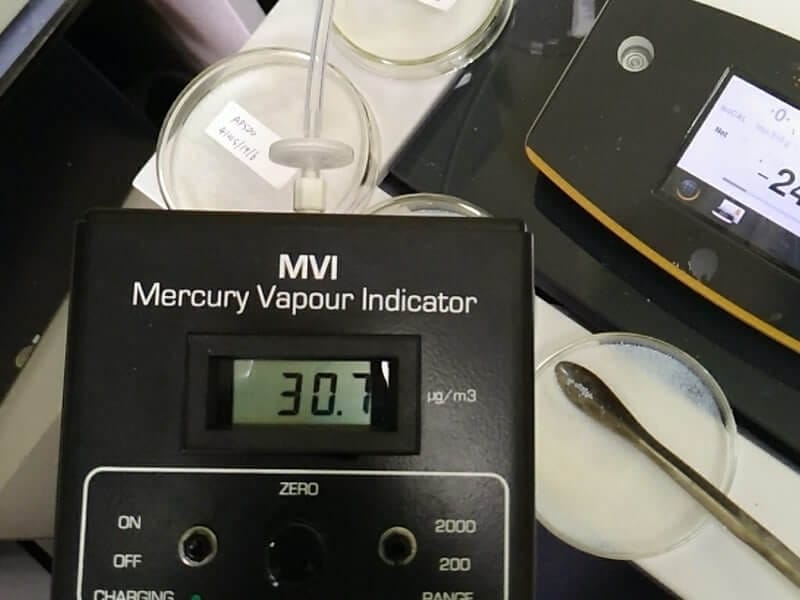

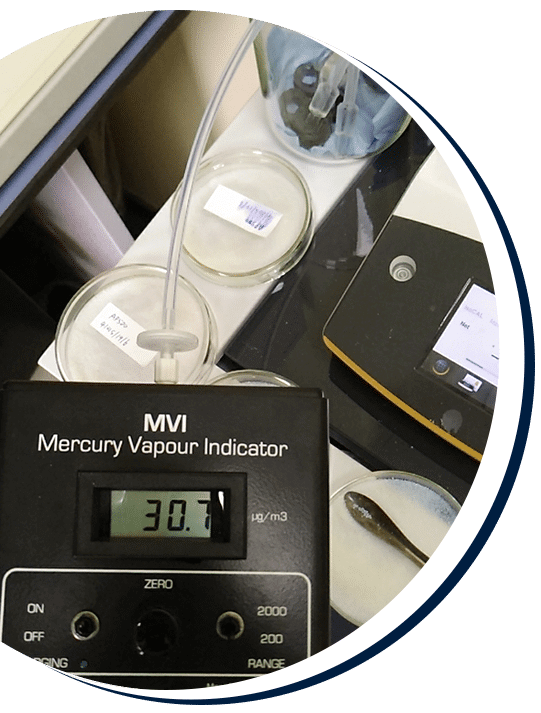

In line with China’s new occupational exposure limits for Chemical Hazardous Agents in the Workplace which took effect on 1 April 2020, Purolite Corporation China is using a Mercury Vapour Indicator (MVI) from global gas detection instrumentation manufacturer, ION Science to help ensure the health and safety of its employees. The handheld instrument is measuring mercury vapour levels in an area used for mercury intrusion porosimetry to calculate the porosity of speciality ion exchange resin technology.

Mercury intrusion porosimetry (MIP) is a technique used for the evaluation of porosity, pore size distribution, and pore volume (among others) to characterise a wide variety of solid and powder materials. The porosimeter employs a pressurised chamber to force mercury to intrude into the voids in a porous substrate. As pressure is applied, mercury fills the larger pores first. As pressure increases, the filling proceeds to smaller and smaller pores.

Purolite

”“We chose the ION Science MVI over competitor instruments due to its simple, lightweight design and ability to detect mercury within three seconds, as well as the after sales service and technical support.”

Xihau Yu: from Purolite

Client name

Client name