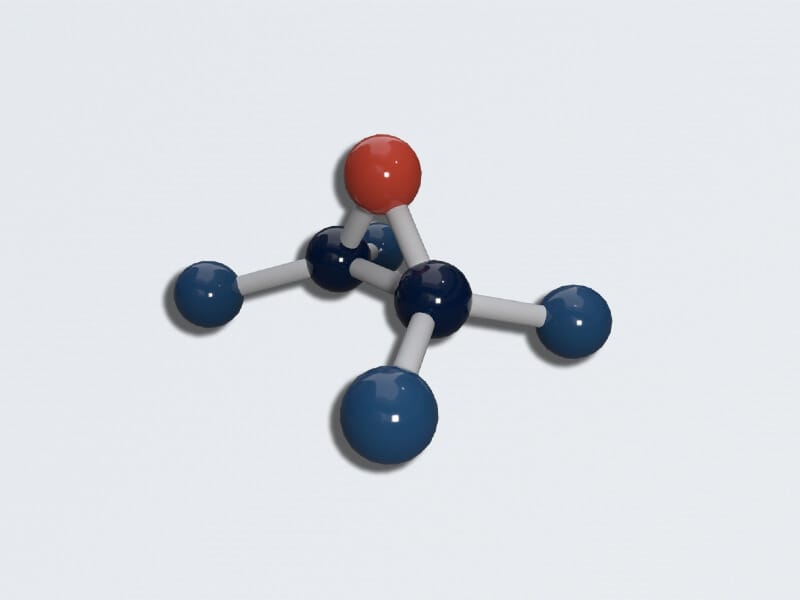

Ethylene oxide

Formula: C2H4O | CAS: 75-21-8

Ethylene oxide detection: The ability of ethylene oxide to damage DNA makes it an effective sterilising agent but also accounts for its cancer-causing activity.

Ethylene oxide detection when using it within the medical industry

The main disadvantages associated with ethylene oxide (ETO) are the lengthy cycle time, the cost, and its potential hazards to patients and staff; the main advantage is that it can sterilise heat- or moisture-sensitive medical equipment without deleterious effects on the material used in medical devices.

Most occupational exposures to EtO are covered by the OSHA standard. The standard does not apply, however, when employers can demonstrate that the processing, use, or handling of products containing EtO will not release airborne concentrations of EtO at or above the standard’s action level of 0.5 ppm

– OSHA Fact Sheet

Identifying Ethylene oxide detection early to limit the routes of exposure

The primary routes of human exposure to ethylene oxide are inhalation and ingestion, which may occur through occupational, consumer, or environmental exposure. Because ethylene oxide is highly explosive and reactive, the equipment used for its processing generally consists of tightly closed and highly automated systems, which decreases the risk of occupational exposure.

Gas Factsheet

Everything you need to know about ethylene oxide detection

Our Gas Factsheets which is available to download below provides you with key information on the exposure limits and the locations of where potentially harmful gases can occur. We also share information on gas detection monitoring techniques and equipment that can help you manage gas detection in the workplace, for worker and site safety.

Ethylene oxide detection

Formula: C2H4O | CAS: 75-21-8

Synonyms: oxirane, dimethylene oxide, oxane, 1,2-epoxy ethane, C2H4O, ETO

Ethylene oxide is the starting point for a wide variety of chemicals, most importantly ethylene glycol and polyethylene glycols.

United Kingdom

United Kingdom