Falco Fixed VOC Gas Detector is being used across the globe to monitor and detect hazardous gas leaks in the manufacturing process of electric vehicle (EV) batteries.

Introduction

Back in 2020, the UK Government took a huge step forward to achieve net-zero by announcing a ban of sales of new petrol and diesel cars by the 2030. This announcement has put the UK on course to be the fastest G7 country to decarbonise cars and vans. A 2 phase approach will be put in place to achieve this target. Step 1) Phase out the sale of new petrol and diesel cars and vans by 2030. Step 2) Every newly manufactured car and van to emit zero emissions from 2035. Between 2030 and 2035, the sale of new cars and vans will be permissible if they possess the capability to travel a considerable distance without emissions, such as plug-in hybrids or full hybrids. Source: www.gov.uk

With less petrol and diesel vehicles being manufactured, the world turns to the need for electric vehicles. There are multiple benefits of owning and using an electric vehicles, including:

- Reduced Emissions: Electric Vehicles produce zero emissions, meaning they don’t have a negative impact on air pollution and greenhouse gases.

- Lower Operating Costs: Eletricity is generally cheaper than gasoline or diesel, resulting in lower fuelling costs.

- Convenience: Many Electric Vehicle owners can charge their vehicle at home, meaning they can simply plug in their vehicle and charge it over night.

Lithium-ion batteries and the associated dangers

Electric vehicles are the short to medium term future of transportation, offering numerous advantages over traditional internal combustion engine vehicles, including reduced greenhouse gas emissions and improved air quality. However, the production of the lithium-ion batteries that power these vehicles comes with its own set of challenges, particularly in terms of safety.

High-capacity lithium-ion batteries, commonly found in electric vehicles, have the capability to recharge fully with minimal energy loss. They are typically composed of carbon or graphite, a metal oxide, and lithium salt, which constitute the positive and negative electrodes. These components are combined with electrolytes to facilitate the flow of electric current. At the end of their useful life, these batteries can be disassembled, allowing for the reuse of raw materials, with approximately 80 percent of the components being recyclable.

The primary components within lithium-ion batteries used in electric cars include the anode, cathode, separator, electrolyte, and lithium ions. EV battery cells typically contain approximately 17 pounds of lithium carbonate, 77 pounds of nickel, 44 pounds of manganese, and 30 pounds of cobalt. It is noteworthy that lithium is the most crucial component in EV batteries, and there is currently an unprecedented demand for this material.

Lithium-ion batteries are known for their high energy density and rechargeable nature, offer versatile applications but also pose risks that require attention. Potential hazards include thermal runaway, wherein the battery can overheat and even explode if damaged or exposed to high temperatures. Short circuits may lead to fires, and physical damage such as membrane punctures can cause internal harm. Overcharging, overheating, manufacturing defects, chemical reactions, aging, and external factors can also compromise battery safety.

The ION Science photoionisation detection (PID) sensors are able to detect potential problems before they occur in the manufacture and use of Li-ion batteries and the enormous variety of devices that use rechargeable batteries. With our ever-evolving digital age, the safe utilisation of Li-ion batteries is of paramount importance to manufacturers and customers. Click here to read the full ‘Li-ion battery risks reduced by VOC sensors’ blog.

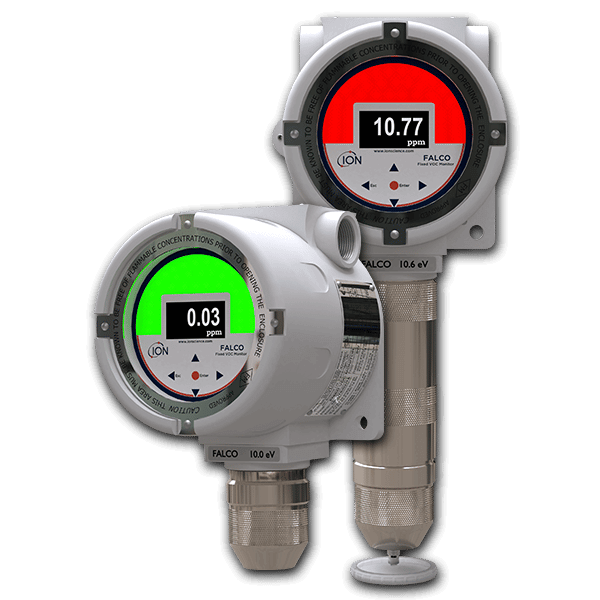

Falco: The Cutting-Edge Fixed VOC Monitor

The Falco Fixed VOC Gas Detector continuously detects a wide range of volatile organic compounds (VOCs) and total aromatic compounds (TACs) using patented photoionisation detection (PID) technology. This fixed instrument plays a crucial role in ensuring the safety of works and the overall manufacturing process when producing lithium-ion (li-ion) batteries for electric vehicles (EVs). Falco is being used in multiple stages of the EV battery manufacturing process but is increasing being used to detect any leaks in individual cells. If a leak occurs, it could lead to a fire or even an explosion, therefore, it is essential that no leaks are present. The Falco Fixed VOC Gas Detector is used to detect the presence of any leaking gases at an early stage, reducing the changes of any life threatening accidents later down the line.

Key Features of Falco include:

High Sensitivity

Falco boasts a high sensitivity to a wide range of VOCs, ensuring that leaks are detected promptly.

Continuous Monitoring

It provides real-time, continuous monitoring, allowing for immediate response to any abnormal levels of VOCs.

Customisable Alarms

Falco allows for customisable alarm settings, alerting facility personnel when VOC concentrations exceed safe levels.

User-Friendly Interface

The user-friendly interface makes it easy for operators to set up and use the device efficiently.

Low Maintenance

Falco requires minimal maintenance, reducing operational costs and downtime.

Multiple Output Options

Falco has 2 programmable relays, 3 – 20 mA output and RS485 MODBUS.

Certified

Falco is ATEX, IECEx and QPS certified.

Protecting Lives and Preserving the Environment

The implementation of Falco fixed VOC monitors in EV battery manufacturing facilities is not just about compliance with safety regulations; it’s also about ensuring a sustainable future. These monitors help in preventing VOC emissions into the atmosphere, which can have long-term adverse effects on air quality and climate change. By promptly detecting and addressing leaks, EV battery manufacturers contribute to a greener and more sustainable world.

At the heart of ION Science’s business vision lies a simple yet powerful mission:

…..

“To protect lives and preserve the environment”.

This encapsulates their unwavering commitment to creating products and solutions that enhance safety while minimising environmental impact. For years, ION Science has been at the forefront of the industry, offering accurate and reliable technology that detects harmful gases and volatile organic compounds (VOCs), making workplaces safer and ensuring a healthier planet.

Conclusion

As the electric vehicle revolution accelerates, the importance of safe and sustainable battery manufacturing cannot be overstated. Falco, the cutting-edge fixed VOC monitor, stands as a beacon for the industry. With its highly sensitivity, real-time monitoring, and remote access capabilities, it is revolutionising how EV battery manufacturing facilities protecting their workforce and the environment.

By choosing Falco, these facilities are not only complying with safety regulations but also actively contributing to a cleaner and healthier planet. As the EV industry continues to grow, Falco will continue to play an indispensable role in safeguarding both the workforce and our shared future.

Contact us today

To discuss with the instrumentation team how Falco can be used in your application.

United Kingdom

United Kingdom