The Dangers Associated with Asphalt Production and Benzene Exposure.

In the early stages of the production of asphalt, managing exposure and minimising risk is critical for worker safety.

The prevalence of asphalt (commonly known as bitumen) in our surroundings, often stemming from the construction industry is widespread – spanning roads, pavements, buildings, and contributing to a vast global asphalt market. Although benzene is a group 1 carcinogen, it is often present in the early stages of asphalt manufacturing due to the utilisation of crude oil.

Given the carcinogenic nature of benzene, safeguarding workers involved in the asphalt manufacturing process against exposure is imperative.

Even at low levels of exposure during production, employees may encounter acute symptoms, including headaches, dizziness, and irritation of the eyes, skin, and respiratory system. Prolonged exposure can escalate these symptoms into chronic conditions such as blood disorders, cancers, and risks during pregnancy.

High numbers of personnel are involved in the manufacture of asphalt all over the world, and protecting workers against benzene exposure risks is imperative for businesses. While some recommendations and laws exist, OSHA however does not currently have any legal requirements around asphalt fumes and preventative measures, beyond general respiratory and PPE safety. Laws exist around general emissions, VOCs, and carcinogens associated with asphalt production, however there is very little currently in place specific to benzene exposure.

With major infrastructure schemes such as the Road Improvement Scheme 2 (RIS2) in the UK, and Norway’s ambitious Route E39 coastal highway scheme (including an underwater floating tunnel section), asphalt will continue to be a critical ingredient of developing infrastructure. Businesses are looking to get ahead of the law changes now by using a ‘safety first’ approach and bringing in additional or updated benzene monitoring systems to their production facilities.

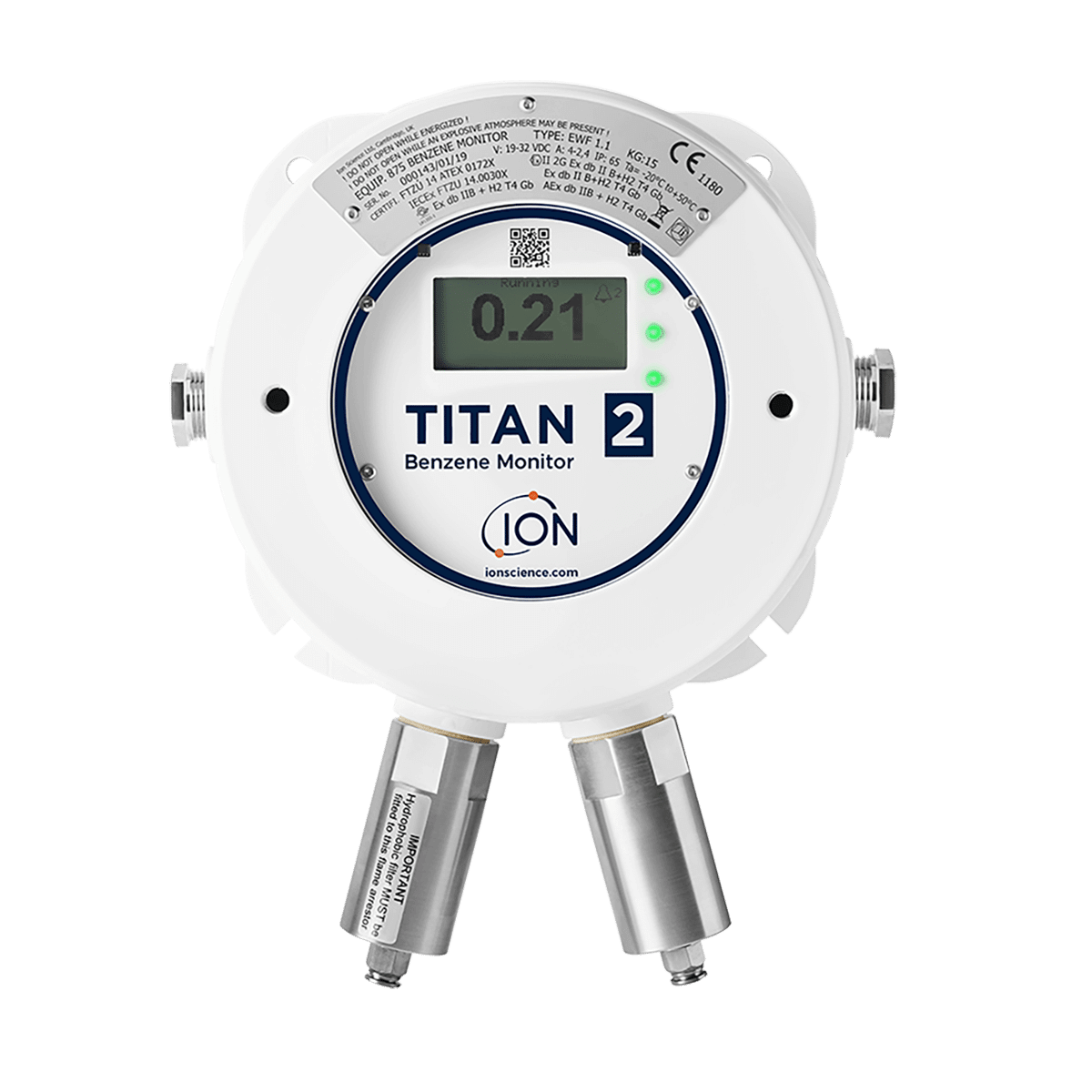

Leading OEM, ION Science, are committed to protecting personnel with their range of gas detection instruments and sensors. Titan 2, the latest addition to ION Science’s fixed instrument portfolio, is the only fixed PID gas detector on the market specifically for detection of benzene, making it the perfect solution for measuring benzene within asphalt manufacturing plants. Titan 2 offers a world-leading solution for the detection of benzene, capable of gas speciation and accurately detecting benzene down to as low as 0.02 ppm (20 ppb) and as high as 20 ppm within a span of 60 seconds. Titan 2 is designed to sample airbourne hazards for the safety of your workforce on site.

This device incorporates the NEW MiniPID T2 10.0 eV which offers improved sensitivity, reliability and overall performance. The unique sampling method eliminates interfering gases providing you with accurate benzene concentration readings you can rely on.

Titan 2 is certified for use in ATEX zoned locations and environments, additionally, the enclosure is IP65 rated which provides protection against dust and water ingress. This allows the detection module to remain operational even in challenging conditions or areas with high levels of dust and humidity.

Any manufacturing plant that handles asphalt production should look to install a Titan 2 unit as part of efforts to protect workers from exposure. For more information on Titan 2, download the brochure below.

United Kingdom

United Kingdom